We decided to test 3D printing technology for non-standard housing projects. Naturally, there were challenges — complex shapes, smooth curves, and unusual radii. But as it turned out, with the right approach, everything is possible.

Smart Build Service helped us adapt the project, explained acceptable tolerances and printing features.

Once we ran the first tests, we knew — it works. Now we’re launching our first demo house and, if all goes well, we’ll scale from there.

The equipment is great, the team is involved — we’re confident that with this partner, we can reach a whole new level.

Oh, and the mix — they already have one that works perfectly, which saves us a ton of hassle. Without proper concrete, nothing useful gets built.

It was important for us to find a solution that suits eco-housing and works well in remote locations.

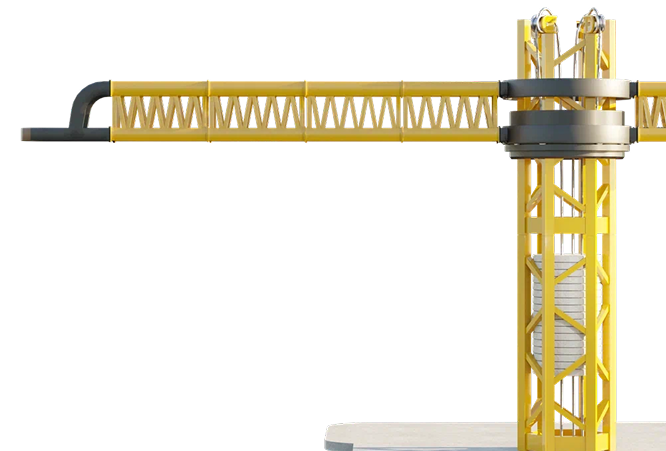

The 3D printer from Smart Build Service turned out to be perfect: autonomous, reliable, and with a user-friendly control system.

They immediately got us involved in the process — explained how to design for printing, what materials to use, and how to save time on-site.

Right now, we’re working on three pilot projects, and it’s great to see their team supporting us at every stage.

It feels like we didn’t just buy equipment — we entered into a full-fledged partnership.

We were looking for a new approach to low-rise construction — especially interested in speeding up the process without sacrificing quality and creating something truly unique.

We were aware of 3D construction technology but had doubts about how realistic and suitable it was for our needs.

We contacted the Smart Build Service team, got clear answers, explored sample projects, and even attended training.

It helped a lot that we could discuss the equipment, design process, and technical printing details all at once.

We’re now adapting our architectural solutions for this technology and plan to launch this spring.

Currently awaiting printer production.

We chose the printer as an alternative to monolithic construction for low-rise projects.

It took time to explore all the details — we work with complex projects.

We even planned how to print internal columns to minimize material usage and avoid frequent start-stops of the printer.

We discussed design nuances and printing specifics — this is the kind of thing that can only be tackled through collaboration.

Luckily, the Smart Build team has the experience.

We’re optimizing our projects financially and beginning construction.

No questions about the printers — we tested everything ourselves at their training center.

The structures come out solid, rigid, precise — no issues at all.