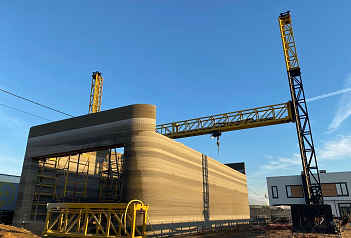

Construction 3D printers are robotic construction complexes for building houses, commercial structures, small architectural forms or building elements - prefabricated buildings (for their later delivery, layout and assembly). Construction uses the technology of additive (layer-by-layer) contour printing of walls with fast-hardening concrete and their subsequent filling with various materials for individual goals and tasks of each project. Additive technologies greatly simplify the process of designing and construction of any architectural forms.

Mortars based on cement and gypsum binders, as well as polymer sand mixtures are used for printing.

Before starting the work, the program for preparing the work file cuts the model into layers, after which the printer applies the prepared mixture to the printing area with the help of a printing head (extruder). The equipment adds building material layer by layer and forms a rigid frame - the outer and inner part of the walls. Thanks to this technology, it is possible to create durable and aesthetic structures of various shapes, including the most complex and unusual projects in construction.

Types of 3D printers for building houses

Construction 3D printers differ in the method of feeding construction mixes and structural design. There are three main types of printers:

- Gantry printers (XYZ printers). The X axis is made in the form of two parallel tracks on which two columns of the Z axis move on a carriage of the original design. Between the Z-axis columns, also on the original design carts, the Y-axis traverse moves vertically. The extruder of the printer, moving in X, Y and Z directions, prints the model with the construction mixture, moving along each of the axes according to the previously set parameters. The gantry equipment is suitable for printing industrial facilities, warehouse complexes, residential buildings, as well as for the production of small architectural forms.

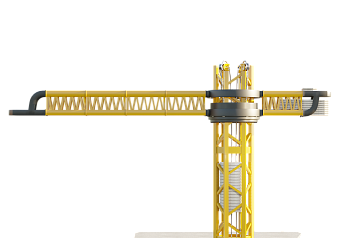

- Crane. Designed for construction of multi-storey facilities, including apartment buildings. Such equipment is placed inside the building as the working area is determined by the reach of the boom. Crane printers also move along a given trajectory and lay down the building material in a continuous line.

- Manipulator printers. These robotic systems can move in multiple planes. These printers are limited in range and are not suitable for creating large objects.

Gantry printers are also capable of producing elements of buildings and structures using prefab technology. With the help of such complexes, individual building modules are created in factory conditions, from which the finished object is then assembled at the construction site.

Что можно создать с помощью строительного 3D-принтера

|

Architectural details

- Capitals, columns

- Decorative facade panels

- Brackets and consoles

- Cornices, reliefs and pediments

|

Элементы ландшафтного дизайна

- Benches

- Fences

- Fountains

- Gazebos and Pergolas

|

Модульные элементы

- Retaining walls

- Bridge supports

- Prefab elements of various configurations and purposes

- Modular structures for temporary and permanent use

|

задач.

As a result, we can say that with the help of construction printers can create objects both directly on the construction site, and assemble them from parts pre-printed in the factory, and gantry printers - are best suited for such a wide range of tasks.

Why buy a construction 3D printer from Smart Build Service

It is important to know what affects the result so that you can influence it. For this reason, we work daily to improve the recipe of the printing compound, as well as to develop and expand our range of equipment, both of which guarantee high results in this field. Our goal is to work with you to actively develop this technology and support you at every stage (including the construction of your first projects) - so you can focus on developing, profiting and realizing your ideas. In addition, there are a number of important points in construction, kitting and maintenance that differentiate Smart Build Service from other players in the market:

- The printer's support elements have been reinforced to resist wind loads and sagging under its own weight.

- Each axis has its own servo drive, chain drive and chain tension adjustment station.

- Positioning accuracy of +/- 1 mm is ensured by the use of high precision equipment and the use of a double drive chain with fine pitch, which in turn ensures the best print quality.

- The extruder is designed with a mechanism that automatically stops the compound feed when it passes through door and window openings. The shut-off mechanism stops the feeding synchronously with the feeding station, which prevents the feeding hoses from clogging and increases their service life.

- The basic set is equipped with a foam concrete mixer and a special mortar preparation and feeding station located directly on the construction site, which reduces the fixed costs of material purchase by more than 2.5 times.

-

The operator's workstation is located in the printer's control center, and all electronics are protected from the elements and unauthorized access. A compact remote control unit with moisture and dust protection is provided to improve print quality and make adjustments easier.

-

Maximum site height difference up to 3 m. The X-axis has a high degree of rigidity and can be placed on both pavement and gravel fill.

-

Printer training takes 40 hours and includes theoretical and practical parts. If necessary, the training period can be extended to consolidate the knowledge gained. We want your team to work efficiently.

-

The warranty period for the equipment is 1 year from the date of purchase.