Thanks to a team of experienced professionals, we find new solutions every day for current construction tasks and the implementation of projects of any complexity.

Innovative technologies

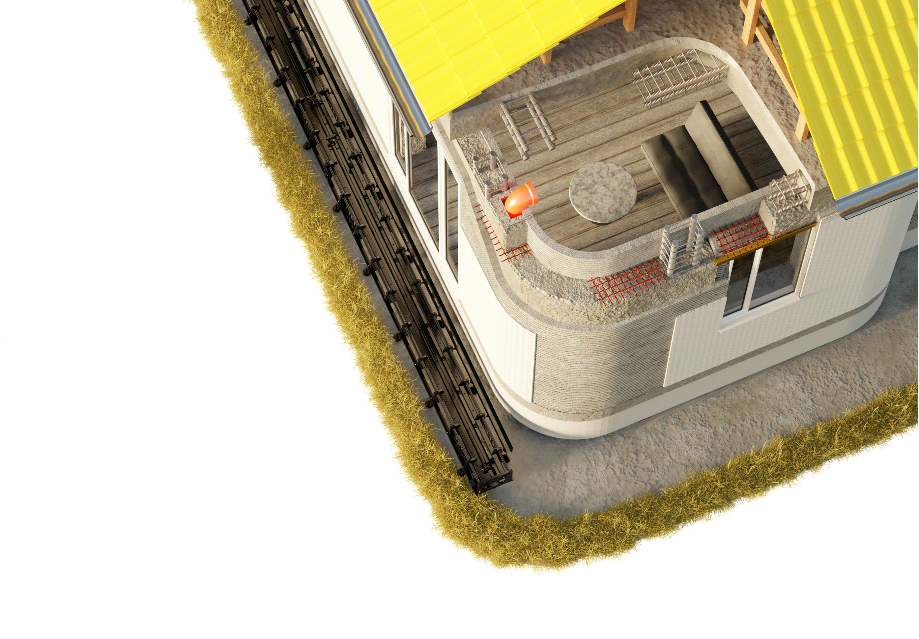

With the help of modern construction 3D printers it is possible to build houses of different shapes and sizes. Specialized complexes allow you to print both small private cottages and large format multi-storey residential buildings.

Printing a house on a printer is much faster and more convenient than building it using traditional technology. Full automation eliminates human error and improves the quality of construction. 3D printers create buildings with complex architecture: curvilinear, multi-level, non-standard format, embodying any idea of the architect or client.

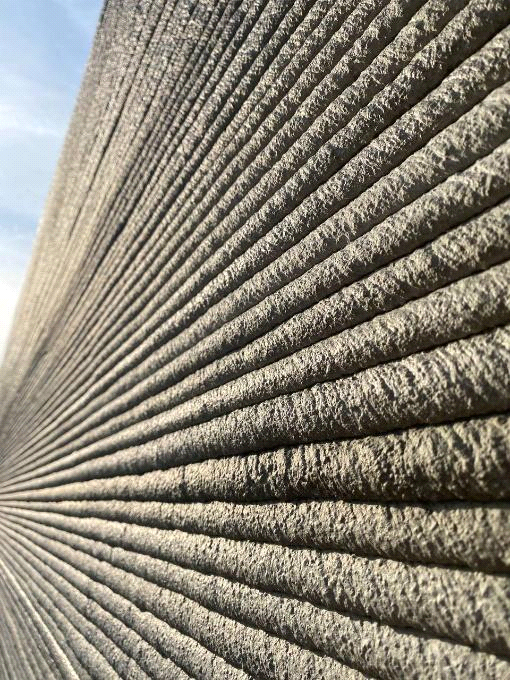

For the construction of buildings and structures using 3D printers, the method of straight contour printing is used. The equipment builds wall contours from fast-setting mixtures: fine-grained concrete, gypsum, and polymer sand compositions. The printed wall frameworks are then filled with foam concrete or other materials as required by the project.

The basis of 3D printing technology is additive synthesis, the step-by-step creation of an object based on a three-dimensional model directly at the construction site.

Additive technologies are used to create both individual building elements and small architectural forms, as well as entire buildings.

The technology of layer-by-layer application of construction mixtures allows you to experiment: use pigments to create colored elements, aggregates and polymer additives that increase the strength of concrete products, their color or other properties.

We manufacture portal and crane printing systems. The construction printers of Smart Build Service work with the contour printing method - they form the outer and inner contour of the walls of houses and apartment buildings of various sizes, any kind of buildings, structures or fortifications.

The construction of a house consists of several stages. The work is done step by step according to the digital model. Printing starts from the foundation and gradually builds the structure vertically:

During operation, the print area can be adjusted to suit the project. For example, you can increase the print area by installing additional elements, or print individual areas in the center of the building to create islands.

It is also possible to print a house using prefabrication technology. In this method, a structure is built from elements that are created in advance on a 3D printer under factory conditions. These printed elements are brought to the site and mounted on a prefabricated foundation.

Fine-grained mixtures based on concrete, foam concrete, polymer composites and gypsum are used for 3D printing of residential buildings. They are loaded in advance into automated mixing stations, which are part of the basic equipment of our construction complexes.

The recipes of the mixtures are constantly improved: the proportions of the components are changed according to the size and type of the construction, as well as according to the construction tasks.

We tell you how an innovative approach helps the modern construction business

Speed and mobility

Construction of houses without lengthy preparation thanks to the mobile design of the complexes and minimal preparatory work. Installation takes no more than 3-4 hours

Convenience

Smart Build Service 3D printers are more modern and advanced than their foreign counterparts, making them easier to transport and more convenient to use on construction sites.

Reliability and quality

The equipment has a long service life and is designed for round-the-clock, heavy-duty use. All printers are assembled and tested at the factory before shipment to the customer.

Result-oriented

Regular deliveries of ready mixes for high quality 3D printed houses. Create materials tailored to the specific project and climate.

Support and guarantees

Support at every stage of cooperation. Support, personnel training, technical assistance and warranty service for one year after purchase and for the entire period of operation.

Additional services

If necessary, it is possible to upgrade the purchased equipment by installing additional modules or individual elements. You don't need to buy a new printer - we have made it possible to upgrade any model.